What are the benefits of a properly balanced plumbing system?

What does balancing a hydraulic system mean, and when is it done correctly?

A hydraulic system ensures optimal operation when it is well-balanced, meaning when the heat transfer fluid flow rates supplying the system’s terminals are correct and regulated.

When balancing occurs correctly, greater thermal comfort, reduced energy consumption, and operation under design conditions are achieved.

Balancing valves ensure this practical and precise flow rate regulation.

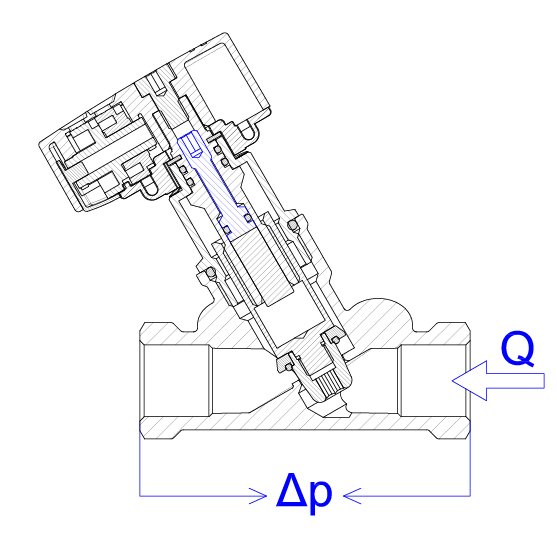

ICMA balancing valves in a hydraulic system allow for precise and gradual flow rate regulation. By turning the adjustment handwheel, it is possible to set the pressure drop and, consequently, the flow rate of the heat transfer fluid supplying the heating and cooling system terminals.

Energy savings and greater comfort

When a system is not optimally balanced, the outlets do not perform their function efficiently, resulting in different temperatures in different rooms. These differences not only cause discomfort but also increase energy waste.

On the other hand, with the use of balancing valves, the plumbing system will have perfect water distribution throughout the system, ensuring comfort in every room and reducing costs.

For this reason, local and European regulations recommend the use of balancing valves as the primary factor for energy savings.

Lower risk of overheating and wear

Balancing valves are now considered indispensable by designers, installers, and plumbing technicians to ensure system efficiency.

Their use allows the performance expected during the design phase and the customer’s requirements to be achieved, as the circulators are enabled to operate at higher efficiency.

As a result, the system is less likely to overheat and also prevents premature wear.